Devices Layout —Graphical illustration of an aseptic processing process that denotes the relationship amongst and amongst gear and personnel. This layout is Employed in the

Regardless of these strategies, the aptitude from the procedure to generate sterile goods should be validated to function in accordance with pre-set up criteria.

Advanced robotics and automated guided vehicles (AGVs) are progressively being used to transport products and gear within just cleanroom environments, reducing the necessity for human entry and exit.

Environmental checking is a crucial element of preserving sterility in pharmaceutical cleanrooms. It will involve the systematic sampling and Assessment of air, surfaces, and staff to detect potential contaminants. As cleanroom technology advancements, so way too do the solutions and tools for environmental monitoring.

MODBUS is an industry common serial interaction protocol for speaking in between devices. FARRAR items with MODBUS allow for people to connect FARRAR products to their monitoring options like neighborhood and cloud primarily based methods.

Documentation and Validation: Each individual step from the cleanroom operation, from environmental checking to cleaning techniques, has to be documented to guarantee compliance with regulatory standards and provide traceability in the course of inspections clean room classification in pharma or audits.

Designed with Recurrent entry storage, clinical demo kitting, and logistics prep procedure requirements in your mind

Aseptically processed merchandise involve brands to pay for near notice to depth and to take care of arduous self-control and demanding supervision of staff so that you can maintain the extent of environmental excellent suitable for the sterility assurance of the ultimate product get more info or service.

Validation makes certain the fumigation process persistently achieves a 6-log reduction in microbial load. Important phases include things like:

These packages frequently contain updates on new rules, rising sterilization technologies, and lessons learned from industry incidents.

The evolving regulatory landscape is pushing pharmaceutical corporations to undertake extra proactive and knowledge-pushed ways to cleanroom sterilization, by using a give attention to steady enhancement and danger mitigation.

Temperature and Humidity: Environmental variables like temperature and humidity are carefully regulated to stop products degradation or microbial growth.

characterize particular person check final results and are proposed only as guides. Each company's data should be evaluated as part of an Over-all checking software.

In isolators, the air enters the isolator by way of integral filters of HEPA high-quality or improved, and their interiors are sterilized commonly to a sterility assurance amount of ten -6; thus, isolators include sterile air, usually do not exchange air Using the encompassing natural environment, and they are freed from human operators.

Neve Campbell Then & Now!

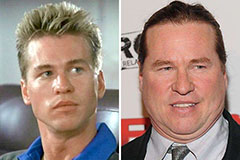

Neve Campbell Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!